A partnership between Australian company National Ports Corporation and engineering giant ThyssenKrupp Industrial Solutions has seen the development of a cost-effective solution that could see the capacity of Port Hedland, the world’s largest bulk export port, increase by more than 70 per cent – with no capital expenditure, additional dredging or changes to existing materials handling processes and equipment.

National Ports Corporation Chairman John Jenkin said a focus on operational efficiencies to improve tonnage throughput remains a key driver for the iron ore industry.

But a steady flow of mid-tier and emerging miners achieving key project milestones and investment decisions more recently could see Port Hedland Port could reach its planned expanded 577 million tonnes per annum (mtpa) capacity in less than three years.

The Port’s capacity was previously set at 495mtpa, with a record annual throughput of 460.4mtpa achieved at Port Hedland in 2015/16 financial year – up from 447mtpa in the 2014-15 financial year.

“The common problem for BHP Billiton, Fortescue, Roy Hill, Atlas and others wanting to increase tonnage or gain access to the Port Hedland port facilities is the capital expenditure required for port infrastructure and the ability of the port to support growth due to both the tide and the depth of the port,” he said

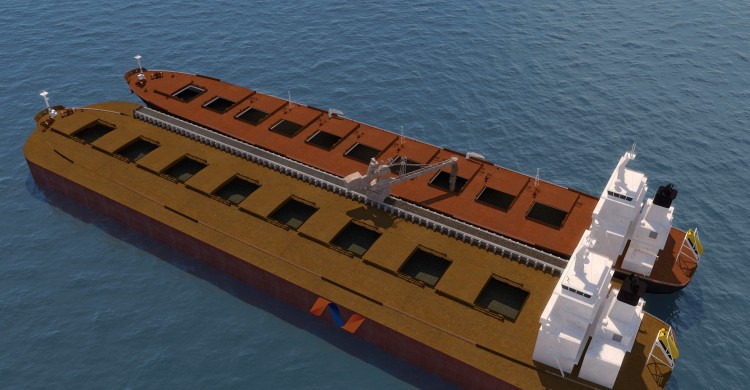

The solution is a built-for-purpose Super Shallow Draft Bulk Carrier complete with a self-loading and unloading facility that can tranship its cargo at a rate of up to 10,000 tonnes per hour into any size bulk carrier (including the Valemax with a 400,000 tonne deadweight capacity) or directly at the destination port in a safe and environmentally friendly manner.

Dr. Franz-Maria Wolpers, Senior Executive in the Mining Technologies business unit of thyssenkrupp Industrial Solutions said: “We are delighted to be helping our clients solve one of the most complex challenges they face when operating in shallow, restricted and remote ports.”

“In addition to opening up access to those ports the new system dramatically increases self-unloading rates into any type of bulk carrier or to the port of destination through a ThyssenKrupp materials handling system.

“In cooperation with National Ports, we are thus offering mining companies and port operators worldwide significant efficiency improvements including faster materials handling at lower cost and reduced environmental risk.”

Mr Jenkin said the Super Shallow Draft-Bulk Carrier (SSD-BC) design incorporating thyssenkrupp’s self-loading and unloading facility makes the offering a game changer.